W3_Afra_Pareto Analysis

1. Problem

Recognition

Working in

Project Risk Register and update it should be one of the critical work for each

phase process from the owner’s perspective.

To looking at

causes of any problem, decision maker shall use a creative way to do that such

as Pareto analysis because it helps stimulate thinking and organize thoughts

which also known as 80/20 rule -assumes that the large majority of problems

(80%) are determined by a few important causes (20%).

In this blog,

I’ll use Pareto analysis to identify the problem and create a plan to improve

the efficiency for a steam turbine ST-050 which was 90% efficient, and because

of some reasons/issues, it becomes 60% efficient.

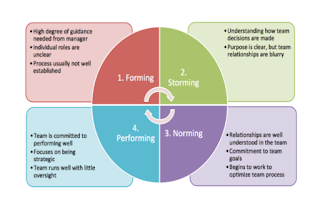

Figure 1 - 4 steps in performing a Pareto Analysis

2. Feasible alternatives

To improve the

efficiency of ST-050 I need to determine the main causes of the problem and

take recovery actions rather than go through each issue separately because there

are more than 30 problems that recorded.

The figure below

shows the ST-050 performance for first 4 months (Feb to May) before applying

any improvement, the figure clearly shows how the production of the steam

turbine (MW) was decreased each month.

Figure 2: ST-050 Performance for first 4

months

Based on the

performance shown, corrective action was required. In this case, Pareto

analysis was conducted to determine the root cause analysis. Once root causes

are found, the issue with the highest impact can be addressed to improve the ST-050

performance.

3.

Development of the outcome of Alternative

To implement

Pareto, all type of problems, a frequency of occurrence, the production loss

for each problem needs to be collected. Then, a list will be produced for all

problem from the major problem to the least problem.

The list of 10

main problems that reduced the efficiency of ST-050 is Blade losses, First stages of the

turbine, Last stage of the LP, Fan losses downstream, Fluid flow, valves,

Piping, Casing, Rotors, and Bearings.

4.

Selection Criteria

The major problems that

cause 85% of all the loss will be listed in Pareto Chart. The rest of the

problems are minor and affecting the performance by 15%.

5.

Analysis and

comparison of the Alternative

Below

Table shows 10 types of major problems that reduce the efficiency of ST-050.

Table 1: Major problems that reduce the

efficiency of ST-050.

The

Pareto chart for the previous table is shown below.

Figure 3: Pareto Chart for Major problems that

reduce the efficiency of ST-050.

6. Selection

of the preferred Alternative

According

to Figure 3 above, the ranks of the first 5 problems (from the major to least

problem) will be Blade losses, Fluid flow, Fan losses downstream, Piping and Last

stage of the LP which contributed to 85% of the total issue. The suggested way

is to find the most effective solution for those top 5 problems to recover the

performance of the ST-050.

7.

Performance Monitoring

and the Post Evaluation of result

Even if the problem

has been solved, monitoring the frequency and occurrence of each problem is

really required so we can understand how effective the solution we did.

In my coming blogs,

I’ll work again to categorized these problems into groups and use other tools

and techniques to identify the root cause of each problem and to make an

improvement plan to solve each group of problems separately.

References:

1.

GUILD OF PROJECT CONTROLS COMPENDIUM

and REFERENCE (CaR) | Project Controls - planning, scheduling, cost management

and forensic analysis (Planning Planet). (2017). Planningplanet.com. Retrieved

20 November 2017, from http://www.planningplanet.com/guild/gpccar/risk-opportunity-monitoring-and-control

2. Pareto Chart in

Excel.

(2017). Excel-easy.com. Retrieved 20 November 2017, from http://www.excel-easy.com/examples/pareto-chart.html

3.

Pareto Analysis Diagram including an example and template

| ToolsHero. (2017). ToolsHero. Retrieved 20 November 2017,

from https://www.toolshero.com/problem-solving/pareto-analysis/

Excellent case study Afra!!! Be sure to remember for Step 7 is that we should do a "before" and "after" Pareto to make sure that whatever interventions we implemented actually solve the problem and didn't just "kick the can down the road" (passing the problems on to someone else)

ReplyDeletehttps://www.qimacros.com/pareto-chart-excel/pareto-analysis/

BR

Dr. PDG, Jakarta